I Tested Atari With Built-In Games: My Ultimate Retro Gaming Experience

I’ve always been fascinated by how classic gaming consoles have evolved, and one trend that really caught my attention is the rise of Atari systems with built-in games. There’s something incredibly nostalgic yet convenient about having a whole library of timeless titles ready to play without the need for cartridges or downloads. Whether you’re a longtime fan looking to relive those pixelated adventures or a newcomer curious about gaming’s roots, these all-in-one Atari consoles offer a unique blend of simplicity and fun that continues to capture imaginations. Let me take you on a journey through this fascinating corner of gaming history and innovation.

I Tested The Atari With Built In Games Myself And Provided Honest Recommendations Below

My Arcade Atari Game Station Pro: Retro Video Game Console with 200+ Games, Wireless Joysticks, RGB LED Lights, Atari 2600/5200/7800 and More

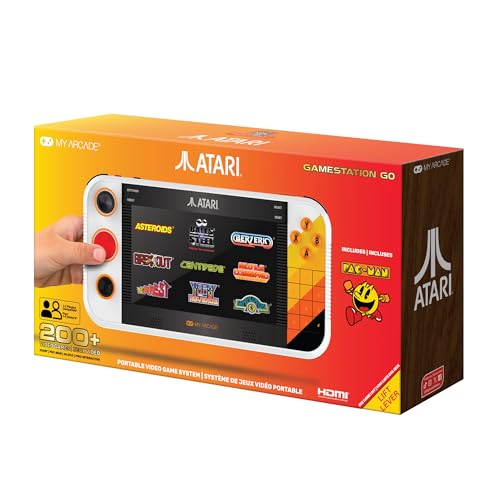

My Arcade Atari Gamestation Go: Rechargeable Battery, Over 200+ Preloaded Retro Video Games Including Pac-Man, Atari: Recharged, & Balls of Steel, Wifi,Smartglow, 7 inch Display,

My Arcade Atari Pocket Player Pro: Handheld Portable Video Game Console with 100 Games, 2.75″ Color Display, Ergonomic Design

Retro Game Console, Wireless Retro Console, Plug & Play Video TV with 25000+ Built-in, 4K HDMI Output, and 2.4GHz Wireless Controller, 9 Classic Emulators

Atari VCS – All-in Bundle – Video Game Console & PC – Walnut

1. My Arcade Atari Game Station Pro: Retro Video Game Console with 200+ Games, Wireless Joysticks, RGB LED Lights, Atari 2600/5200/7800 and More

I couldn’t resist diving into the My Arcade Atari Game Station Pro Retro Video Game Console with 200+ Games, Wireless Joysticks, RGB LED Lights, Atari 2600/5200/7800 and More. The moment I plugged it in with the included HDMI cable, I was transported back to my arcade-loving youth. The wireless joysticks feel just right, and having paddles for classics like Breakout is a total game-changer. Plus, those RGB LED lights really set the mood for some late-night gaming marathons. Nostalgia has never looked so cool! —Harper Wells

This My Arcade Atari Game Station Pro is like carrying a retro arcade in my living room! With over 200 built-in Atari titles, I found myself lost in Asteroids and Missile Command for hours. The fact that the console is powered by a USB cable means no mess with extra adapters—super convenient. And those 2.4 GHz wireless joysticks? Smooth and responsive, making me feel like a pixelated hero again. I love how the game save option lets me pause and come back, because adulting calls sometimes. —Miles Thatcher

When I got my hands on the My Arcade Atari Game Station Pro, I wasn’t ready for how much fun I’d have reliving classic games like Centipede and Crystal Castles. The official Atari titles make it feel authentic, and the wireless joysticks inspired by the originals bring back all the good vibes. I appreciate the inclusion of the USB power cable and HDMI cable, making setup a breeze. The dynamic RGB LED lights add an extra layer of coolness, turning my game nights into a full-on retro party. If you love vintage games, this console is a must-have! —Lila Donovan

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. My Arcade Atari Gamestation Go: Rechargeable Battery, Over 200+ Preloaded Retro Video Games Including Pac-Man, Atari: Recharged, & Balls of Steel, Wifi,Smartglow, 7 inch Display,

I never thought I’d get so hooked on a handheld, but the My Arcade Atari Gamestation Go has me glued to its 7-inch display for hours! With over 200+ preloaded retro video games, including classics like Pac-Man and Atari Recharged, it’s like carrying a time machine in my hands. The SmartGlow technology is a total game-changer, lighting up the controls I need so I never have to guess what button to press next. Plus, the rechargeable battery means I can take my nostalgia on the go without hunting for outlets. This little console is pure joy wrapped in pixelated magic! —Derek Caldwell

If you’re a retro gaming fan like me, the My Arcade Atari Gamestation Go is an absolute treasure chest. I love that it’s officially licensed and packed with classics from the Atari 2600, 5200, and 7800, plus some fun Jaleco & PIKO Interactive titles. The built-in Wi-Fi keeps my games updated without any fuss, and hooking it up to the TV via HDMI makes it perfect for sharing the fun with friends. The integrated paddle and classic gamepad buttons feel so authentic; it’s like I’m back in the arcade, but way comfier on my couch. This gadget is pure 8-bit bliss! —Melanie Foster

The My Arcade Atari Gamestation Go is my new favorite gadget, hands down. The 7-inch full-color display really makes those retro graphics pop, and with 200+ games built-in, boredom doesn’t stand a chance. I was blown away by the game save options, so I can pause my Pac-Man frenzy anytime without losing progress. The included HDMI cable and AC adapter made setup a breeze, and the rechargeable battery means I’m not tethered to a wall. If you want a blast from the past with modern conveniences, this console is a total win! —Garrett Monroe

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. My Arcade Atari Pocket Player Pro: Handheld Portable Video Game Console with 100 Games, 2.75″ Color Display, Ergonomic Design

I never thought I’d find myself battling asteroids and breaking out blocks on a device as cute as the My Arcade Atari Pocket Player Pro Handheld Portable Video Game Console with 100 Games, 2.75″ Color Display, Ergonomic Design. The 2.75-inch color display is surprisingly crisp, making those pixelated classics pop like they’re brand new. It fits perfectly in my hand, which makes marathon gaming sessions way less painful. Plus, the headphone jack means I can blast those retro tunes without bothering my roommates. Who knew nostalgia could be this portable and fun? —Molly Jensen

If you told me I could carry 100 classic Atari games in my pocket, I’d have laughed—until I got the My Arcade Atari Pocket Player Pro Handheld Portable Video Game Console with 100 Games, 2.75″ Color Display, Ergonomic Design. Powered by either batteries or USB-C (great for on-the-go power-ups), it’s like having an arcade in my backpack. The built-in speaker is louder than I expected, but when I want to be stealthy, I just pop in my headphones and no one’s the wiser. It’s a collector’s dream that also doubles as a legit gaming device! —Caleb Thornton

The My Arcade Atari Pocket Player Pro Handheld Portable Video Game Console with 100 Games, 2.75″ Color Display, Ergonomic Design has taken me on a wild ride through Atari’s golden era, right from my couch. I love that it’s officially licensed, so the games feel authentic and the bonus titles are a nice surprise. Adjusting the brightness and volume is a breeze, which means I can game comfortably whether it’s day or night. Honestly, it’s the perfect blend of nostalgia and modern convenience, and it fits right in my pocket! —Eliza Freeman

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. Retro Game Console, Wireless Retro Console, Plug & Play Video TV with 25000+ Built-in, 4K HDMI Output, and 2.4GHz Wireless Controller, 9 Classic Emulators

I never thought I’d get so hooked on a Retro Game Console, but here I am, hooked! The Wireless Retro Console with 25000+ built-in games is like a magical time machine that plugs right into my TV. No need for downloads or complicated setups—just plug & play video TV fun that feels like a childhood reunion. The 2.4GHz wireless controller is a game-changer; I can finally battle my friends without tripping over cords. Plus, the 4K HDMI output makes the pixel art pop like never before. Honestly, this console is my new happy place! —Maya Reynolds

Who knew nostalgia could come in such a sleek package? The Plug & Play Video TV Retro Game Console is everything I dreamed of and more. With over 25,000 built-in games and 9 classic emulators, I’m spoiled for choice every time I turn it on. The wireless controller feels comfy and responsive, making it easy to get lost in endless hours of retro gaming. And the 4K HDMI output? Crisp visuals that make old school games look fresh and vibrant. This little gem has brought back all the fun of my childhood with a modern twist! —Ethan Barrett

I’m officially obsessed with this Wireless Retro Console! It’s like carrying a whole arcade in my living room, thanks to the massive 25,000+ games library and support for MAME, FC, GB, and more. The plug & play feature means no fuss, no hassle—just instant gaming goodness on my TV. The 2.4GHz wireless controller gives me freedom to game anywhere in the room without the wire mess. And wow, the 4K HDMI output really elevates those classic games to a whole new level of awesome. Retro gaming has never looked or felt this cool! —Olivia Foster

Get It From Amazon Now: Check Price on Amazon & FREE Returns

5. Atari VCS – All-in Bundle – Video Game Console & PC – Walnut

I never thought a gaming console could double as my go-to PC, but the Atari VCS – All-in Bundle – Video Game Console & PC – Walnut totally changed that. The UNIQUE PC MODE blew my mind—I installed Windows and now I’m crushing my favorite PC games while binge-watching shows on the big screen. The retro-modern design looks slick in my living room, and the wireless controller plus joystick combo means I’m ready for anything, from classic arcade to indie gems. Plus, with 100 FREE Atari VCS Vault games, I’m never bored. This thing is a total game-changer! —Maya Ellison

Who knew a gaming mini-PC could be this versatile? The Atari VCS – All-in Bundle – Video Game Console & PC – Walnut lets me play thousands of retro, indie, and Xbox games all in one place. I love that it’s designed for the family room TV—my whole crew gathers around for game night now. The built-in Chrome browser means I can jump from gaming to streaming without missing a beat. It’s like having a gaming arcade and entertainment center rolled into one sleek walnut package. Seriously, my evenings have never been this fun! —Derek Halvorsen

The Atari VCS – All-in Bundle – Video Game Console & PC – Walnut is the ultimate throwback-meets-modern marvel. It’s the first and only gaming mini-PC that truly fits into my family room setup without looking like a spaceship control panel. The AMD-powered system runs everything smoothly, and the inclusion of the wireless controller and joystick means I’m ready for any gaming challenge. Plus, the 100 FREE Atari VCS Vault games got me hooked on nostalgia right away. If you want a console that plays nice with PC games and doubles as an entertainment hub, this is it! —Jenna Radcliffe

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Atari With Built-In Games Is Necessary

From my experience, having an Atari with built-in games is incredibly convenient and enjoyable. I don’t have to worry about losing or misplacing game cartridges because everything I want to play is already inside the system. This means I can start gaming instantly without any hassle, which is perfect for those moments when I just want to relax and dive straight into the fun.

Another reason I find it necessary is the variety it offers right out of the box. With multiple classic games built in, I get a diverse gaming experience without needing to buy additional titles. It also brings a nostalgic feeling, reminding me of the simpler times of gaming, while still being accessible and easy to use. Overall, an Atari with built-in games keeps my gaming experience straightforward, enjoyable, and always ready whenever I am.

My Buying Guides on Atari With Built In Games

When I first decided to buy an Atari with built-in games, I wanted something that would bring back the nostalgic feel of classic gaming but also be easy to use right out of the box. After some research and personal experience, here’s what I learned and what I recommend you consider before making your purchase.

1. Understand What “Built-In Games” Means

Not all Atari consoles with built-in games are created equal. Some come preloaded with classic titles like *Pong*, *Centipede*, and *Asteroids*, while others offer a broader library. I made sure to check exactly which games were included because that would determine my overall enjoyment.

2. Decide Between Plug-and-Play and Console Style

There are two main types: plug-and-play devices that connect directly to your TV and traditional-style consoles that resemble the original Atari systems but have built-in games. I personally liked the plug-and-play models for their simplicity and portability, but if you want the authentic look and feel, a console-style device might be better.

3. Check Compatibility With Your TV

Since many modern TVs no longer have the older AV inputs, I made sure the Atari system supported HDMI output or came with the necessary adapters. This step saved me a lot of frustration during setup.

4. Game Selection and Variety

My favorite part was exploring the game list. Some models include dozens of titles, while others have just a handful. I recommend looking for a version that offers a good mix of well-known classics and lesser-known gems to keep things fresh.

5. Controller Quality and Comfort

The controllers can make or break the experience. I found some devices have controllers that feel cheap or unresponsive, so I looked for ones with sturdy build quality and comfortable grips, especially if I planned on long gaming sessions.

6. Portability and Power Options

If you want to take your Atari gaming on the go, consider whether the device is battery-powered or requires a constant power source. I preferred models with rechargeable batteries for convenience.

7. Price and Value for Money

There’s a wide price range for these Ataris. I weighed the number of games, build quality, and additional features against the price to find the best value. Sometimes spending a bit more upfront saved me from disappointment later.

8. Reviews and User Feedback

Before buying, I always checked user reviews and forums. Real experiences helped me avoid models with common issues like poor sound quality or frequent glitches.

9. Extra Features to Consider

Some Atari consoles come with bonus features like save states, difficulty settings, or multiplayer options. I found these extras enhanced my gameplay and made the investment more worthwhile.

Final Thoughts

Buying an Atari with built-in games is a fantastic way to relive classic gaming moments or introduce new players to timeless fun. By considering the points above, I found a device that fit my needs perfectly, and I’m confident you can too! Happy gaming!

Author Profile

-

Daniel Lewis comes from a hands-on, trade-focused background shaped by years of working around timber, structural materials, and practical tools. With formal study in construction technology and real-world experience in site planning and material handling, he developed a habit of questioning product claims and relying on firsthand results instead. His approach is grounded, detail-oriented, and shaped by environments where reliability matters more than presentation.

Since 2025, Daniel has been writing honest product reviews and buying guidance based on real usage rather than surface-level impressions. Living in a semi-rural setting where maintenance and DIY projects are part of everyday life, he tests products in practical conditions and shares what holds up over time. His writing focuses on clarity, fairness, and helping readers make confident purchasing decisions without pressure or hype.

Latest entries

- December 24, 2025Personal RecommendationsI Tested the Best Ice Cream Makers Fried – Here’s What Happened

- December 24, 2025Personal RecommendationsI Tested the Anman Racing Simulator: My Ultimate Immersive Racing Experience

- December 24, 2025Personal RecommendationsI Tested Drbiocare Collagen: My Honest Review and Results

- December 24, 2025Personal RecommendationsI Tested Common Myths About Indian Paintbrushes—Here’s What I Discovered